Mercedes-Benz has announced plans to retool its production setup for electric drive systems, including batteries, electric drive units, and axles, from 2024.

This follows the company’s realignment of production for electric vehicles based on future vehicle architectures earlier this year.

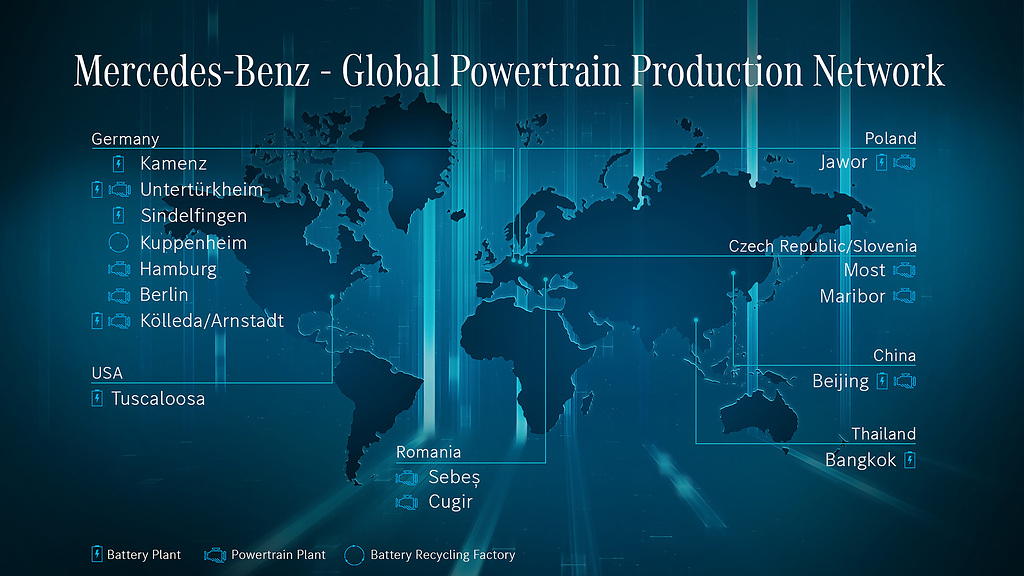

The new production setup will be implemented within the existing Mercedes-Benz powertrain production network, and the company is investing a mid-single-digit billion euro amount in its European powertrain production locations as part of its Mercedes-Benz Business Plan.

The battery plants in Kamenz, Brühl, and Beijing will produce batteries for the new models on the MMA and MB.EA platforms, while the Untertürkheim, Sebes, and Beijing plants will produce electric drive units for the same models.

The Mercedes-Benz plants in Hamburg and Untertürkheim will remain the lead plants for the assembly of electric axles and components, and will supply the Mercedes-Benz body plants with next-generation systems.

The Mercedes-Benz plant in Berlin will produce high-performance electric motors for the AMG.EA platform from the mid-decade.

The new production setup will enable Mercedes-Benz to meet the increasing demand for electric vehicles and support the company’s goal of becoming fully electric by the end of the decade, wherever market conditions allow.

Stuttgart has announced that it will have battery electric vehicles (BEVs) in every segment it serves by 2022 and from 2025 all newly launched vehicle architectures will be electric only.

To support this shift, the company is investing over €40 billion into battery electric vehicles between 2022 and 2030 and is also launching three electric-only architectures: MB.EA, AMG.EA and VAN.EA.

As part of its plan, Mercedes-Benz will also deepen its level of vertical integration in manufacturing and development and insource electric drive technology, including the acquisition of UK electric motor company YASA.

The company will also set up eight factories for producing cells and expand its network of nine plants dedicated to building battery systems. In addition, Mercedes-Benz is working with partners such as SilaNano to increase the energy density of its batteries through the use of silicon-carbon composites.

The company is also developing a recycling process for used batteries that it claims will recover 95% of the raw materials in a closed loop process.

Here are the plants that will be affected by the move to EV

- Untertürkheim: largest location in the network, produces conventional engines, components, and electric drive units, as well as battery systems for EQ models; also houses eCampus, competence centre for battery and battery cell R&D

- Kamenz: produces battery systems for hybrids and electric vehicles, starting battery production for new all-electric Mercedes EQ models in 2024

- Kölleda: assembles 4-cylinder petrol and 4 and 6-cylinder diesel engines for Mercedes-Benz vehicles, establishing battery assembly for new all-electric Mercedes EQ models (subject to support from Thuringian state government)

- Hamburg: produces axles and axle components, steering components, and drive and transmission components; producing electric axles and components for new all-electric Mercedes EQ models from 2024

- Sebes: produces transmission components, establishing electric drive unit production for new all-electric Mercedes EQ models on the MMA and MB.EA platforms from 2024

- Kuppenheim: produces drive and transmission components; building a battery recycling plant (scheduled to start operations in 2024)

- Berlin: producing high-performance electric motors for the future AMG.EA platform from the mid-decade

- Beijing: producing electric drive units for new all-electric Mercedes EQ models on the MMA and MB.EA

- Bangkok produces battery system for plug in hybrids and fully electric vehicles.