If you are learning about EVs or are in the market for one, you may have heard the terms “permanent magnet motors” and “induction motors” used to describe the motors of electric cars. Both are commonly used in electric vehicles (EVs), but they operate differently and have their own set of advantages and disadvantages.

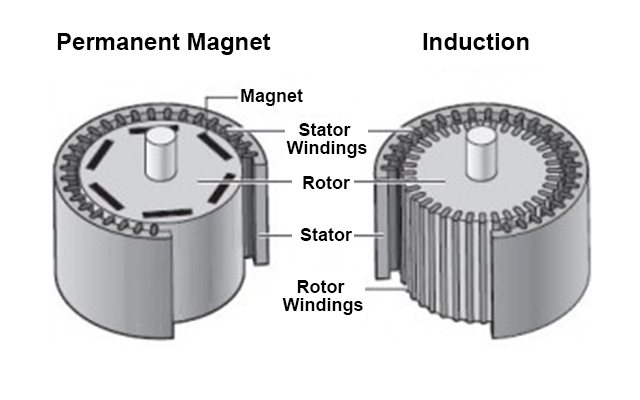

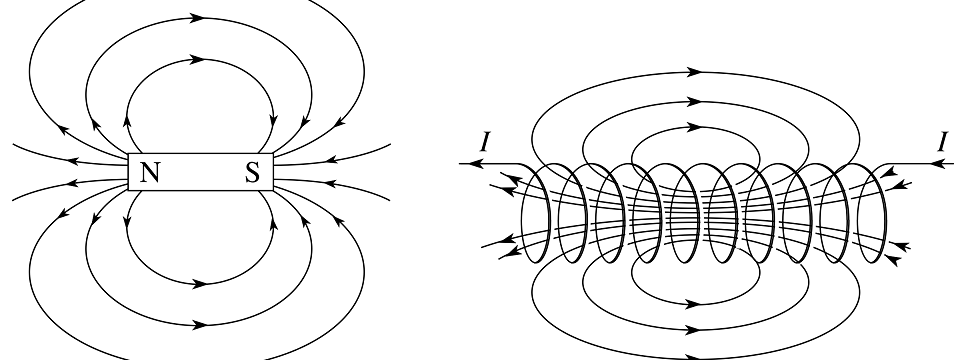

Permanent magnet motors use permanent magnets to generate the magnetic field required for electric motor operation, while induction motors use electric currents to generate a magnetic field using an electromagnet.

Due to this difference in how they generate motion, permanent magnet motors tend to be smaller and lighter than induction motors, making them a popular choice for EVs that need to be compact and efficient.

One major difference between the two motor designs is cost and durability. Permanent magnet motors tend to be more expensive than induction motors due to the rare earth materials (such as neodymium or samarium) used to make their permanent magnets, which are more expensive than the copper and aluminum used in induction motors.

In addition, the manufacturing process for permanent magnet motors is generally more complex and requires more specialized equipment, leading to a higher overall cost. However, the cost difference can vary depending on the specific motors being compared and the performance requirements of the application.

While induction motors are generally larger and heavier than permanent magnet motors, they are also more robust and less prone to damage. They can operate over a wide range of speeds and withstand higher levels of overload without failing. In addition, induction motors do not have any fragile components like the permanent magnets used in permanent magnet motors, making them more resistant to damage.

On the other hand, permanent magnet motors are more sensitive to temperature changes and can be more prone to damage from overloading or overheating. The permanent magnets used in these motors are also brittle and can be prone to cracking or breaking if subjected to too much stress.

Efficiency is another area where permanent magnet motors outperform induction motors, with efficiency exceeding 95% while induction motors can only achieve efficiencies of 80% – 90%.

This is because permanent magnet motors are able to generate more torque per unit of current due to the stronger magnetic field produced by their permanent magnets. This means that a permanent magnet motor can generate more torque with less current, making it more efficient.

Induction motors generate torque by using an electromagnetic field to produce a rotating magnetic field in the stator. This rotating magnetic field then interacts with the magnetic field of the rotor, causing it to rotate and generate torque.

Induction motors are generally less efficient than permanent magnet motors because they require more current to produce the same level of torque. Induction motors also tend to be less efficient at higher speeds because they rely on an electromagnetic field to generate torque, which is less efficient than using a permanent magnet.

Power density, or the amount of power that a motor is able to deliver in a given volume, is another area where permanent magnet motors excel. Permanent magnet motors tend to have a higher power density than induction motors due to their smaller size and the efficiency of the materials used in their construction.

This makes them a good choice for applications where size and weight are important considerations, such as in electric vehicles. However, it is worth noting that induction motors can also be designed to have a high power density, especially when constructed using advanced materials and techniques.

In terms of control systems, permanent magnet motors are typically controlled using a technique called field-oriented control (FOC), which involves adjusting the current flowing through the stator windings of the motor in order to control the magnetic field produced by the stator.

By carefully regulating the current in this way, it is possible to control the speed and torque of the motor with high precision.

Induction motors are typically controlled using a technique called pulse-width modulation (PWM), which involves rapidly switching the current flowing through the stator windings on and off at a high frequency in order to control the average current flowing through the motor.

For example, if the PWM signal has a high duty cycle (meaning that the current is “on” for a large portion of the time), the average current flowing through the motor will be high and the motor will spin faster.

If the duty cycle is low (meaning that the current is “on” for a smaller portion of the time), the average current will be lower and the motor will spin slower.

By carefully adjusting the duty cycle of the PWM signal, it is possible to control the speed and torque of the motor.

Overall, the choice between a permanent magnet motor and an induction motor will depend on the specific needs and requirements of the application.

Permanent magnet motors offer higher efficiency and power density, but are more expensive and less durable. Induction motors are less efficient, but are more robust and less expensive. Both have their own unique set of advantages and disadvantages, and the best choice will depend on the specific needs of the application.

In an EV, it is likely that lower performance applications will rely on induction motors, in fact even in some high-performance models permanent magnet motors are used only in the rear while the front relies on induction motors, this is because the rear axle usually can provide more traction during acceleration and benefits from a more powerful motor.