The news that Tesla has reached a level of 4680 battery cell production that can support the production of over 1,000 cars per week is significant for the electric vehicle (EV) industry.

The 4680 battery cell is a new format that Tesla developed in-house and is a key component of the company’s EVs. The fact that Tesla has been able to ramp up production of these cells to such a high level suggests that the company is making progress in increasing its manufacturing capabilities and improving the efficiency of its production processes.

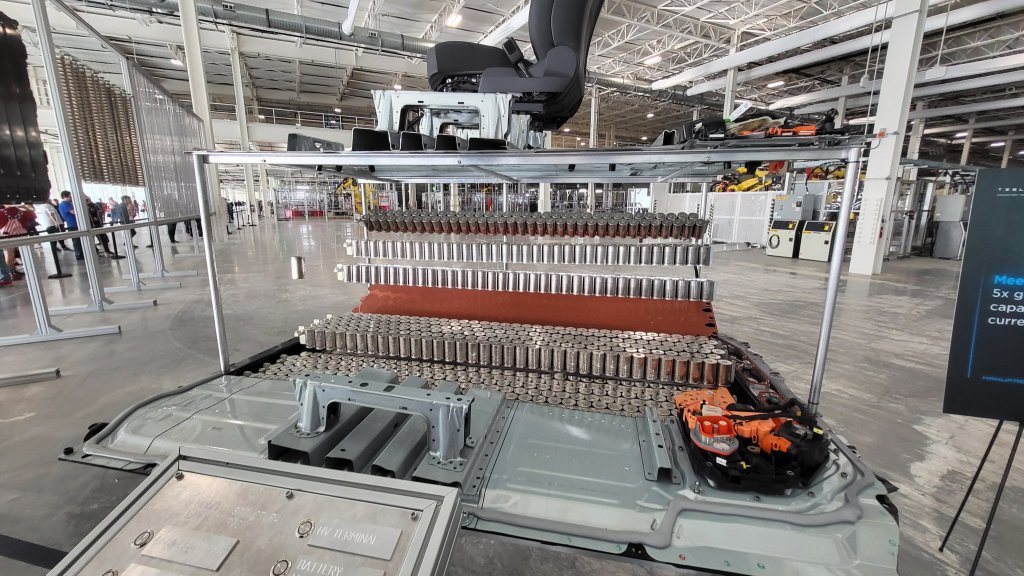

The 4680 battery cell is notable because it is larger and has a different design than Tesla’s previous cell formats, the 18650 and 2170. The new cell is designed with a “tableless” structure, which allows for more space for the active material that stores energy and a greater energy density. This means that the 4680 cells can store more energy in a smaller space, which can potentially lead to longer range and lighter weight EV batteries.

In addition to the pilot plant in Fremont, California, where Tesla has already produced its first million 4680 cells, the company is also establishing higher volume production at its Gigafactory in Texas. This is part of Tesla’s efforts to shorten its supply chain and increase efficiency.

Overall, the news of Tesla’s progress in 4680 battery cell production is a positive development for the EV industry, as it suggests that the company is making progress in improving the performance and efficiency of its EVs. It is also an indication that Tesla is committed to developing and producing its own battery cells, rather than relying on external suppliers. This could give the company a competitive advantage in the EV market and potentially lead to lower production costs and higher profit margins.

Will the 4680 dominate the market?

There are several factors that could influence the adoption of the 4680 battery format or other battery technologies in the automotive industry. These include the performance and efficiency of the batteries, the cost of production, the availability of raw materials and manufacturing capacity, and the overall market demand for electric vehicles (EVs).

One possibility is that the 4680 battery format or a similar format could become the standard for the automotive industry. The 4680 battery format has several advantages over Tesla’s previous cell formats, including a larger size and a higher energy density, which could make it more attractive for use in EVs. However, other companies may also develop their own proprietary battery formats or technologies, and it is not yet clear which format or technology will ultimately dominate the market.

Another possibility is that prismatic batteries, which are a type of lithium-ion battery with a different shape and design than cylindrical cells like the 4680, could become more popular in the future. Prismatic batteries have some advantages over cylindrical cells, such as being more flexible and easier to package, which could make them more suitable for use in certain types of EVs. However, it is not yet clear how widely prismatic batteries will be adopted in the automotive industry.

Overall, it is difficult to predict with certainty which battery format or technology will become the standard in the automotive industry. It is likely that different formats and technologies will be used in different types of EVs, depending on the specific requirements and constraints of each application.

Pros and Cons of 4680

The 4680 battery format is a new cell format developed by Tesla that is designed to have several advantages over Tesla’s previous cell formats, such as the 18650 and 2170, as well as other battery formats. Some of the potential advantages of the 4680 format compared to other formats are:

Larger size: The 4680 cell is significantly larger than Tesla’s previous cell formats, which allows it to have a higher energy density and potentially longer range for EVs.

Higher energy density: The 4680 cell has a higher energy density than Tesla’s previous cell formats, which means that it can store more energy in a smaller space. This could lead to lighter weight and more compact battery packs for EVs.

Tableless design: The 4680 cell has a “tableless” design, which means that it does not have the traditional metal tabs or “tables” used to connect the cells in a battery pack. This allows for more space for the active material that stores energy, which can contribute to the higher energy density of the cell.

Potential for lower production costs: The 4680 cell is designed to be more efficient to manufacture than Tesla’s previous cell formats, which could potentially lead to lower production costs.

Some of the potential drawbacks of the 4680 format compared to other formats are:

Limited production capacity: The 4680 format is a relatively new development, and it is not yet clear how widely it will be adopted by automakers or how much production capacity will be available. This could limit the availability of 4680 cells for use in EVs.

Compatibility with existing battery packs: The 4680 cell has a different size and design than Tesla’s previous cell formats, which could make it more challenging to integrate into existing battery packs that were designed for use with different cell formats.

Potential challenges with scaling production: Tesla has not yet demonstrated its ability to mass-produce the 4680 cell at a high volume, and it is not yet clear how easily the company will be able to scale up production of the cell.

Competition from other battery formats: The 4680 format may face competition from other battery formats, such as prismatic cells, that have different advantages and disadvantages. It is not yet clear which format will ultimately dominate the market.

Overall, the 4680 battery format has the potential to offer several advantages over other formats, but it also has some potential drawbacks that could limit its adoption in the automotive industry. It is likely that different battery formats and technologies will be used in different types of EVs, depending on the specific requirements and constraints of each application.